HOTLINE:

+86-27-87862117

Mobile

Copyright(C)2023,GA Measurement Control Equipment Co.,Ltd. All Rights Reserved. Supported by Toocle 31fabu Copyright Notice

Stable operation without jamming at ultra-high temperature

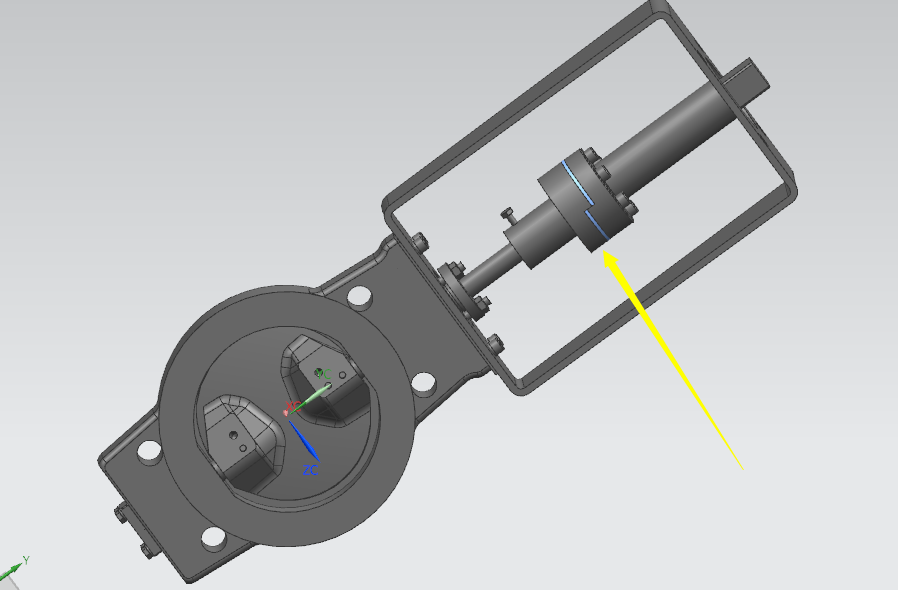

Triple eccentric structure

To cope with high temperature conditions, the valve adopts a double short shaft design, which connects the upper and lower shafts to the valve plate, effectively releasing temperature deformation and avoiding through shaft design. Under high temperature, the valve shaft undergoes creep, causing abnormal switching phenomena.

A reasonable flow channel design and a turtle back style valve plate are adopted, avoiding the design of reinforcing ribs in the shape of a well, preventing vortex and vibration, making it more suitable for high-temperature structures.

Material selection

ASTM A439 D4 is an austenitic ductile iron material that can withstand temperatures up to 1200 ℃. Especially under high temperature conditions, ASTM A439 D4 not only has the corrosion resistance and heat resistance of stainless steel, but also has the advantages of high strength, high toughness, and good wear resistance of ductile iron, with good impact resistance. Therefore, ASTM A439 D4 is a good choice for making shaft sleeves under high temperature conditions. The ASTM A439 D4 shaft sleeve has also been applied in various high-temperature working conditions and has been verified by actual working conditions.

Structural optimization

The connection between the valve body and actuator is made using a raised high-temperature bracket and a concave convex flange structure coupling.

1. The high-temperature bracket effectively isolates the thermal radiation effect of the pipeline medium on the actuator from a spatial distance, and adds insulation pads to the upper and lower planes of the bracket, effectively isolating the pathway of upward conduction of pipeline medium temperature through the bracket.

2. The axial connection adopts the method of connecting with a concave convex flange structure coupling without two upper sections. At the same time, an insulation pad is added to the contact surface of the two couplings, effectively isolating the path of pipeline medium temperature conduction through the valve axial direction and reducing the dead zone range of the regulating valve.

The above two measures have solved the problem of general actuators not being able to withstand high temperatures (high-temperature actuators can withstand temperatures of -20-150 ℃), improved the stability and service life of actuators, and this connection is suitable for use in high-temperature working conditions.